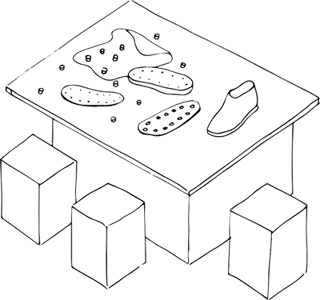

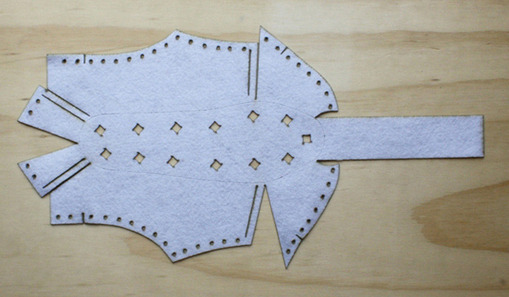

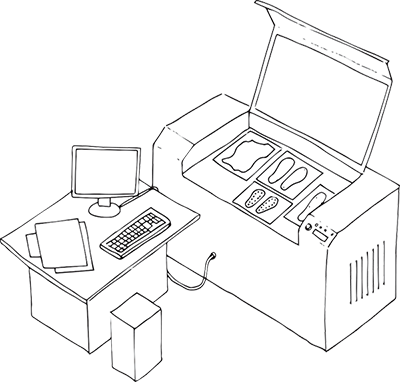

Here’s something awesome. Eugenia Morpurgo and Juan Montero have come up with a new manufacturing system for shoes. Through laser cutters and 3D printers, they’re able to produce design patterns, and then have those patterns transformed into separate components, which they assemble by hand without the need for stitches or glue. Their idea is to take the process of shoe production and bring it directly to the consumer. So, instead of having your shoes made in England or China, the “factory” would be brought into your local store, where you can choose what you want and have your shoes made within an hour.

The system at the moment is still more of a novelty than anything practical, but if it develops, it could have a lot of interesting consequences. For example, it could reduce waste and the need for overproduction, as well as the size of storage facilities necessary for producing and selling footwear. This, of course, could greatly lower our environmental impact. It could also blow open the doors for collaboration and customization, as the manufacturing process becomes more digitalized. And, perhaps if these systems become cheap enough, maybe one day you can have one in your own home, so that you can design shoes based off of templates you’ve downloaded from the web.

You can learn more about the project at Don’t Run (the project’s name) and Domus.